The sample preparation using special cut-off machines is the starting point of any material investigation. High precision cut-off machines are indispensible for successful sectioning of the material, as during this early preparation step, the conditions are created to subsequently obtain precise measurement results. What does that mean? The more precise and gentle the material preparation, the better the results obtained during subsequent analysis. Here, cut-off grinding is the most popular method for sampling.

In order to protect the material from damage due to overheating, wet cutting is considered the best method. For this purpose, SCAN-DIA cut-off machines are equipped with closed cooling water systems which offer the possibility to add special cooling agents and provide lubrication and protection against corrosion. In this domain, SCAN-DIA cut-off machines perfectly meet all requirements in terms of precision and efficiency. They provide for a high cutting performance and ensure that material deformation is reduced to a minimum.

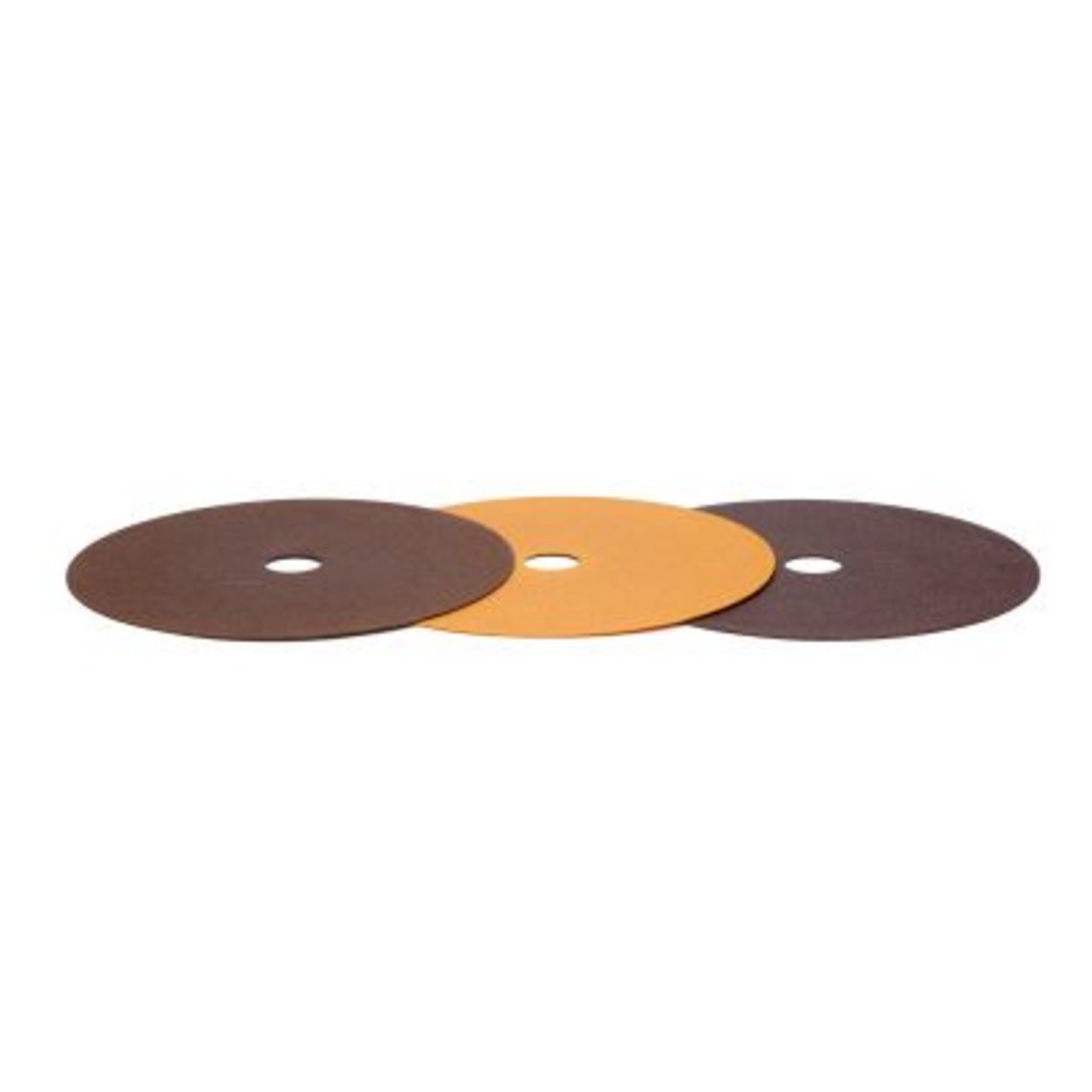

SCAN-DIA supplies a wide range of cutting discs of various types (diverse abrasives and binders) as well as further accessories. Because the right choice of cut-off wheel for a specific material is as decisive as quality and cutting performance in order to obtain precise results.

Overheating protection

A wet cutting process is recommended in order to protect the material from damage caused by overheating. SCAN-DIA cutting machines are therefore equipped with closed cooling water systems which also allow for adding special cooling agents to provide lubrication and protection against corrosion. SCAN-DIA cutting machines perfectly meet all requirements in terms of precision and efficiency. They provide a high cutting performance and ensure that material deformation is reduced to a minimum.

Quality and cutting performance for precise results

SCAN-DIA offers a wide range of cutting discs with diverse abrasives and binders as well as further accessories – because accurate results for a specific material rely as much on the right choice of cut-off wheel as on quality and the cutting performance.

Information

In the field of materialography, part of materials sciences, the structure of ferrous and non-ferrous materials (such as composites, ceramics, and plastics) is studied.

"Metallography" is the study of purely metallic materials.

Materialography wants to quantitatively and qualitatively analyze microstructures by means of various microscope technologies. Statements are made relating to the microstructure as well as to the properties of a material.

First step of the work process is the sample preparation. A material sample is prepared for the microscopic examination of its crystalline structure.

A scratch-free polished section providing a sharp and smooth sample surface is produced, allowing for a representative observation of the material structure. During the preparation, it is particularly important to avoid deformation, smearing, or scratches. Therefore, precise working is required using high quality grinding, polishing, and cleaning agents. Furthermore, depending on the observation criteria, the section may be etched using various solutions.

In general, the materials scientist needs a broad knowledge of material properties, material production, and further material processing in order to avoid preparation errors and errors during the structural analysis.

Materials scientists work in the fields of quality assurance, in failure analysis, and in the research and development domain.

The microscopic examination of the materials provides important conclusions on the production conditions and thus helps to assess production processes as well as to shed light on cases of failure. Moreover, the results of materialographic research build the basis for the development of new materials that are optimally adapted to their respective operating conditions.

Contact

Our experts are happy to answer your questions. SCAN-DIA has a dedicated team of professionals who provide in-depth expertise to offer you personalised support and ensure you get the best possible solution.

Whether you have questions about SCAN-DIA products, technical problems or industry issues, don't hesitate to call. They will be happy to help you with your concerns.